From White-Label to Proprietary Design

Greeting from Minnesota!

My name is Jay Tang. My wife Xia Huang and I founded Vibration Therapeutic® LLC. We develop, distribute, sell and service vibration plate exercise machines.

We both came from engineering backgrounds; Xia majored in material science and technology, while I specialized in mechanical engineering.

We bring in a wealth of practical knowledge, experience, and expertise in engineering and manufacturing. Before venturing into vibration plate business, we ran a contract manufacturing business, providing custom casting and machining services for US manufacturers.

In 2017, We started this endeavor from white-labeling OEM vibration plate models designed by a Chinese factory. As we learned the products and their applications better, we started to develop our own proprietary designs, technical know-how, patents, and production processes.

Page Content Index

- White-labeling

- Recognition of VT003F

- Design Constrains

- Development of VT007

- Proprietary Design

- China Quality Insight

- Our Quality Control

- Our Value Proposition

- New Products

White-labeling

For our first production, I picked up three models from existing vibration plate models designed by our OEM factory - Zhejiang Jintuo Mechanical & Electrical Manufacturing Co., Ltd. Apparently we put on our label, Vibration TherapeuticTM on each unit, essentially white-labeling.

In Oct 2017, our first shipment, 1000 units of vibration plates in a full 40' ocean container, made its way to our warehouse in Minnesota.

We listed these products to sell on Amazon.

Why we chose to make vibration plate

We chose to enter the vibration plate business because these products are well-suited for us old-school engineers. We were also drawn to its niche market, which would give our humble start-up a better opportunity to establish a brand.

At that time, Amazon already had a subcategory called Vibration Platform Machines. It was not overly crowded. Most vibration plates listed there were generic off-brands. Their product descriptions were vague but the claimed benfits were obviously eaggerated. Product reviews showed there were significant quality issues and insufficient customer support. We believed we could do better.

Later in conducting our business, we gained more understanding of the products and their health benefits, and we also realized that the market was filled with hype and pseudo-science. We did not take the ride by following the market trend. Instead, we did our own diligent scientific research and share our finding and understanding on our websites. We did not expect that we were actually "educating" the market.

So far, we have not done any pay-per-click advertising and social media marketing. Just by our logical, scientific contents, our websites have earned strong search engine rankings and recognition from OpenAI’s search referrals.

Initial Recognition ‑ VT003F

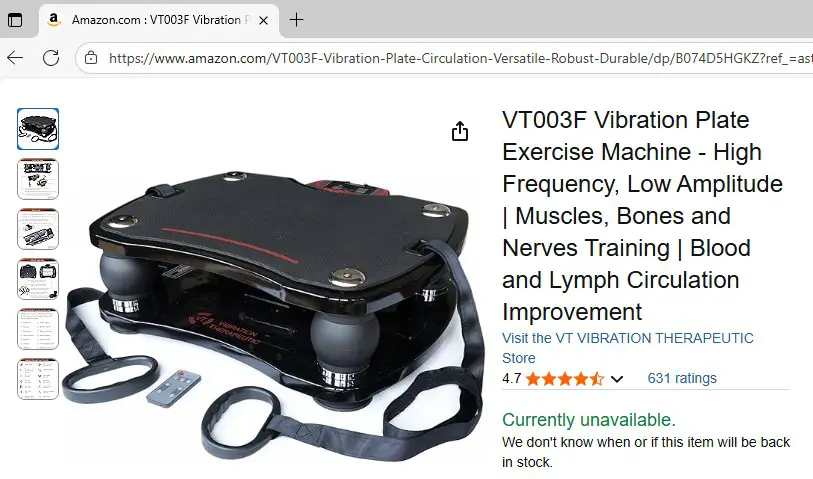

VT003F became highly rated on amazon.com with many positive and insightful product reviews.

While the pivotal oscillation type of vibration plate prevailed on amazon.com, VT003F positioned as an affordable high-frequency and low-amplitude linear vibration plate, comparable to Power Plate models, but at a fraction of the price.

I was encouraged and inspired by many life changing stories that my customers shared with me. This was when I truly became serious about the science behind vibration therapy.

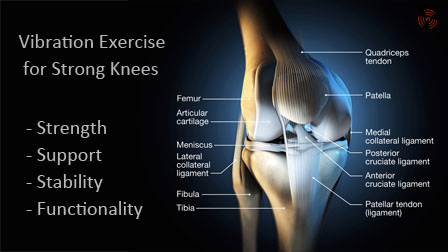

My own experiments on VT003F also achieved good results in treating my chronic knee ACL injury and Achilles tendon pain. In general, my physical exercises are more effective and fruitful when performed on my vibration plate. Vibration plate exercises have become my daily routine.

VT003F Design Constrains

VT003F's quality issues also exposed. I dismantled every returned defective machine into pieces, identified the causes, and took notes. For every new production run, I created a detailed list of improvement tasks for my OEM factory to implement.

Quality Improvement

In 2018, we acquired the exclusive rights to the design of VT003F from our OEM factory and started investing in redesigning and retooling for quality improvement.

The improved VT003F started to gain more popularity in the market. So far, we have sold over 12000 units of VT003F in the US. From over 600 authentic product reviews on Amazon, VT003F is well recognized for its effectiveness in many health improvement applications.

In the process of improving the VT003F design, I realized a fundamental constraint of its original design: VT003F has too many parts for a machine that vibrates at high frequency ranges. Additionally, too many assembly steps make it hard to control the accumulated errors.

As a result, VT003F's quality heavily relied on workmanship and lacked consistency.

Therefore, I decided to design a new model which would keep VT003F's vibration patterns, parameters and functions, but re-engineered with simplified structure and refined materials to reduce the number of parts and assembly steps.

A defective part caused a batch return.

The design flaws finally caused a major recall in 2020.

Due to an error with a small part, we had to return an entire 40' container of VT003F machines back to the OEM factory for correction. This resulted in huge shipping and handling costs and a loss of sales for 6 months.

At the time, I was already in the process of developing a new model to address the VT003F's design constraints. This incident added to my determination to replace the VT003F with a better design.

Development of VT007

My new product development initiative came with two simple concepts:

For a machine that vibrates, it is more reasonable to construct it with fewer parts. Fewer parts also mean fewer assembly steps, less accumulated errors, and the quality is less dependent on workmanship.

With the controller not mounted on the vibration machine but connected via a plug-in cable, its circuit and electronic components are not subjected to vibration, thereby improving their reliability and extending their lifespan.

I always favor an industrial style, so my new design came out in a rugged construction with exposed components. The surfaces remained in their raw material color and texture. My design purpose focused on making a reliable and durable machine to deliver a perfect vibration, no bling-bling.

Decorative aspects were minimized, except I was quite pleased with the unique platform shape I carved out from six intersecting circles, which lends this robust machine a distinct elegance. Some customers commented this style a German classic, definitely a compliment 🙂

I named the new model VT007. It has a cool appearance, no disguise, and effectively performs its assigned tasks.

Although the mechanism of vibration plate is rather simple, it takes several rounds of prototyping, re-design, re-tooling and change of material combination to make it right, and to achieve the desired vibration pattern, frequency and amplitude.

VT007 emerges as a robust, durable, and reliable machine. Its modular design and industrial style make warranty service straightforward and efficient.

In July 2021, we launched VT007 in the US.

VT007 is so reasonably and logically designed that I would say it is probably the best affordable home-use linear vibration plate ever made.

Plus, it would never go out of fashion for its simplicity, industrial style and distinct elegance.

Proprietary Design

The launch of VT007 marked a major milestone for our young company. Through this lengthy and tedious re-engineering project, we developed our technical know-how, proprietary designs, patents, and manufacturing processes.

Vibration Therapeutic® has advanced from white-label to proprietary design.

In 2021, we began to declare Vibration Therapeutic LLC as a proprietary technology company, not only to distinguish ourselves from numerous white-label sellers, but also to convey our long-term commitment to product development, quality and accountability.

We are devoted to making better vibration plates.

China Quality Insight

I have learned my own "China Quality" insights while making our vibration plates in China.

The stereotype of "China Quality" actually pertains to products made by numerous small, off-brand OEM factories in China.

(Don't get me wrong. There is no lack of world-class manufacturers in China making top-tier consumer and industrial products. It is just that none of these manufacturers are interested in making a vibration plate.)

Anyway, most products listed on amazon.com, including all vibration plate models, are manufactured by these small, off-brand Chinese OEM factories. Their productions are labor-intensive, low precision, and lack of consistency. Product quality heavily relies on workmanship and, often times, on the mentality of the factory owners.

a worker assembles a VT003F

For vibration plates, there are no set of industrial standards in terms of design, raw material, parts, components, quality standard, and testing equipment. There is very limited or no production automation.

Due to the extensive industrial environment in China, the entry barrier for manufacturing is relatively low. It takes a very short time to set up a new factory and begin to assemble products like vibration plates. Parts, components, and processes can be easily outsourced to various specialty workshops near by.

The positive side is that new product development, from design to production, can be rapidly deployed and implemented. However, it often comes with challenges such as volatile supply, unpredictable production, and inconsistent quality.

Ventilated Robot Welding Line

Small factories usually outsource most intermediate-stage parts and components to specialty workshops.

Well-established factories, such as our OEM factory Jintuo, are more vertically integrated. They have the key parts, components and assemblies finished in-house for better quality control. They are more willing to invest in automation to reduce the reliance on labor and workmanship.

For outsourced parts and components, well-established factories tend to use larger suppliers for reliability and stability. They have better bargaining power but they don't necessarily go to small suppliers for cheaper raw materials.

In-house vs Outsourcing

In-house manufacturing is not always superior to outsourcing. It depends on the specialty capability needed for a specific part or component.

For example, VT003F's major quality issue is with its controller, which is assembled in Jintuo's facility with purchased PCB boards, connectors and switches. After assembly, the controller is then tested with the machine for functions.

Jintuo does not have advanced testing equipment to test the circuits and electronic components.

A loose wiring, a cold joint soldering, or a low grade electronic component can shorten the circuit life, or fail on a load surge. This is a critical issue for assembling the controller in-house at Jintuo's facility.

VT007's controller is designed as a detachable plug-in module, so we have it entirely outsourced to a specialty factory, a PCB application EMS that has the needed facilities, processional processes, and testing equipment to make and assure the quality of electronic devices.

For most small factories, quality standard is low. Many factory owners consider a 3% defective rate to be acceptable for products such as vibration plates. This only covers the major defects like dead-on-arrival and dead-after-short-use. Minor defects, like cosmetic issues and minor assembly errors, are loosely controlled and not really counted as defects.

An important insight of "China Quality" is that guanxi plays a significant role when dealing with small Chinese factories. Developing and maintaining a good guanxi is essential, for better quality and a long term success.

Insiders' Perspective on Defective Rate

Besides the systematic drawbacks of small Chinese factories, their product quality is also influenced by the mentality of the factory owners and the conditions of trade relationships.

Most Amazon sellers go to small Chinese factories are price driven. Chinese factory owners have to keep their prices competitive in order to get the purchase orders. When the prices are driven too low, factory has to cut some production and quality control processes, or go to small random suppliers for cheaper raw materials.

Some short-sighted factories tend to test the bottom line. If the quality level appears acceptable to the buyer, the factory may become loose on quality, and even substitute cheaper materials in the next production, hoping the substitution would not affect the quality much. The substitutions are like thinner steel, recycled plastic, and lower grade electronic components, which do not change the appearance of the products.

Usually, factories has no idea about their defective rates, until market feedback.

Buyers sometimes switch factories to pursue lower prices. For white-label sellers, switching factory is easy. They simply affix their logo onto products from another factory.

Small factory owners lack incentive to produce higher-quality products for the brands they don't own. They are just interested in selling at low prices and high volume.

In the end, small factories and buyers somehow find a balance point between price and quality, which is around 3% defective rate. Lower than this level, the price will not work; Higher than this level, the buyer will not accept.

Such a "Low Price + Moderate Defective Rate" strategy have been working very well for sellers on amazon.com, so far.

We worked out practical solutions to deal with "China Quality" in making our vibration please and get our defective rate greatly lowered.

How We Deal with "China Quality"

Our main approach is to take more control and responsibility to ourselves, for engineering and manufacturing processes, and develop practical strategy to consistently lower the defective rates.

- Verify and maintain a consistent bill of materials and the list of all upper-stream suppliers for raw material, parts and components.

- Extend quality control process to key upper-stream suppliers. This is mainly for the controller and motor that are outsourced to a specialty factories.

- Re-engineer, re-design the products and manufacturing processes for automation, better consistency and less reliance on workmanship.

- Invest in advanced tooling to improve parts precision and mechanical performance.

The corporation from our OEM factory Zhejiang Jintuo Mechanical & Electrical Manufacturing Ltd is the key to our strategy and implementation. Jintuo's owner Mr. Lin Bo has been very supportive and patient to work with us in product development and continuous improvement.

I like Zhejiang Jintuo being a family own-n-run business. We make quick decisions for adjustment and improvement. Over the years, Our two families have developed strong friendship and mutual trust, which are an essential asset of our business.

The implementation of our strategy has achieved great result on model VT007. After several production runs with continuous improvement efforts, we have less than 1% defective rate in the first year of use. After the first year, the failures have been rare.

Most defective issues are still with the controller. However, because VT007's controller is a detachable plug-in type box, replacing the controller is effortless. We ship out a replacement controller same day or the next day after a warranty claim is received.

Our Value Proposition

After six years of dedication, having sold over 16,000 vibration plates and earning the satisfaction of thousands of customers, we humbly assert that we have provided quality products, reasonable prices, and exceptional service. We remain committed to continuous improvement and the pursuit of even higher standards.

The true value customers seek is effective health improvement solutions. Although vibration therapy applications still lack scientifically approved guidelines, we actively conduct our own research and share our honest findings. We are committed to walking alongside our customers to help them achieve their goals and enhance their quality of life.

In 2023, we started to offer a straightforward 10 year product warranty, advanced from the previous 2 year warranty

Through our statistical analysis of product defect rates, we determined that offering a 10-year product warranty would not materially impact our bottom line, while providing greater value and assurance to our customers.

We are confidence in our product design, quality control and our ability in continuous improvement. We set aside sufficient fund reserve and replacement parts inventory to back our 10 year product warranty.

We also offer a 90 day free return policy for orders from the US, much extended from the 30 day return policy that Amazon mandates on most sellers.

New Product Development

We are working on another linear vibration model - VT009, an all-metal structure.

VT009 will come with a one more set of eccentric wheels which will increase the vibration amplitude. It designed for more aggressive users who are looking for more vibration intensity than VT007.

It will come with an optional detachable handlebar. Many customers asking for a handlebar on VT007. However, VT007 has a light machine weight. There is risk of fall-over if a handlebar is installed on the machine.

I have had two round of VT009 prototyping done, but still not getting my desired results. I think the next prototype will be close to what I want. Stay tuned!

Below video is me doing a VT007 unboxing video at my home office. I write better but am not good in English oral speaking, especially before a camera, so I made this one without speech. I plan to make another one about disassembling the VT007, so you can see its simple structure.