VT003F Quality Issues & Fixes

VT003F linear vibration plate is our legacy model which we have sold about 12,000 units. It is highly praised for its effectiveness in various health improvement applications. However, due to its design constrain, VT003F has inconsistent quality issues and higher defective rates. We finally stoppped making the VT003F after 2022, and replaced it with better designed model VT007. The last unit of VT003F inventory was sold out in November 2024.

We continue to service the VT003F for at least 10 years after purchase.

| Purchase Date | Warranty Term |

| Before August 2022 | 2-Year Warranty | 10 year replacement parts supply |

| After July 1, 2022 | 10-Year Warranty | No out-of-pocket expense for customers for any warranty service. |

Replacement parts can be ordered from out eStore.

Below are the common quality issues and fixes for the VT003F.

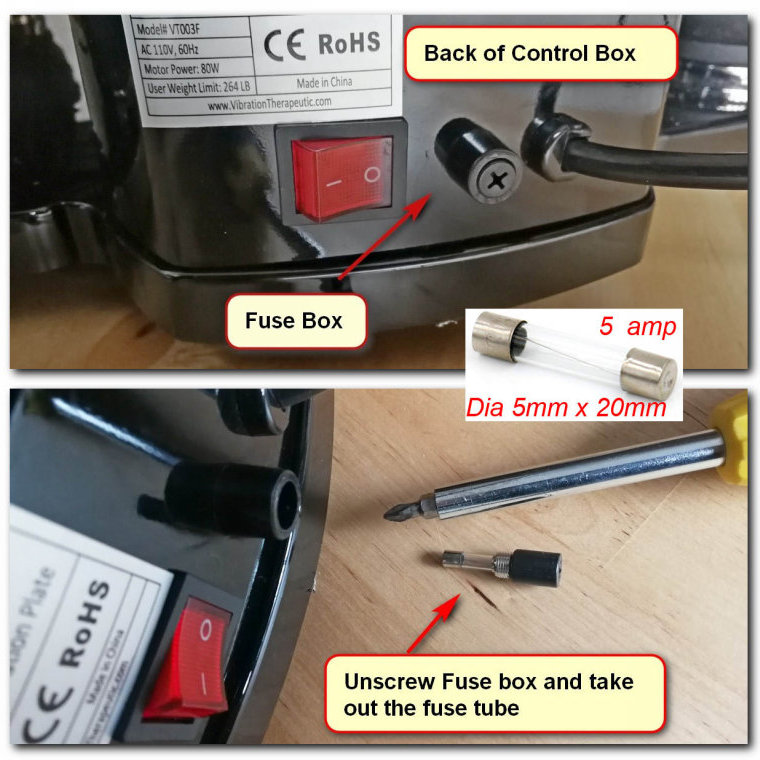

Fuse Blown

If machine is dead (no light), you may first try to replace the fuse. VT003F's fuse is a 5 Amp 20mmx2mm size tube. Please unplug the machine from the electricity supply before replacing the fuse. The fuse box is located next to the power switch at the back side of the control box. You can use a Philip screwdriver to unscrew the fuse cap, and replace the fuse. See the demo picture below.

Fuse blown issue can be complicated. It may be a sudden power surge or a defective control console circuit or electronic component.

Defective Control Console

Control console issues are usually fuse blown or malfunction due to defective circuits, defective electronic components or accidental current surge. The issues may appear as machine dead without light, machine turned-on to run on the highest speed with no control, or control signal mess-up.

Replacing control console is not difficult. The control console is connected to the motor using a 3-pin connector (white color). There is no wiring or soldering work involved to replace the control console. The connector is fixed on the bottom plate with a metal bracket. A cable tie binds the male part and female part of the connector together for additional connection security.

Step-by-step instruction of replacing the control console.

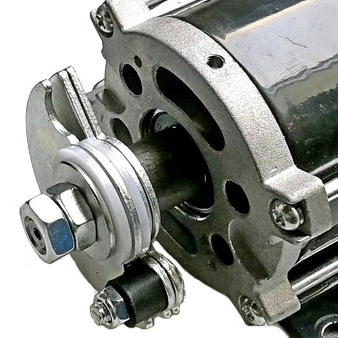

Motor Issue

VT003F vibration plate is driven by a 80W DC motor. The motor defective rate has proved to be very low. Out of over 8000 units of VT003F sold by mid of 2021, only about half a dozen defective machines were the motor issue, about 0.1% defective rate.

Over years, the carbon brushes of the DC motor will wear out. Depending on the rotation speed it runs, the DC motor is designed to run on an average lifespan of 2000 to 3000 hours before the carbon brushes need to be replaced. For regular home use, the VT003F motor would last for about 15 years, no maintenance needed.

Remote Control Problems

Defective remote controls are not counted in our machine defective rate. We ship out replacement remote control via USPS Priority Service immediately after we receive a remote defective report.

We found in many cases, the problems with remote control were that users did not point the remote control to the control panel. The remote control uses infra-red light to transmit signal, just like TV remote. It needs to point to the signal receiving window on the control panel to work.

By design, some buttons are disabled in certain situation, for logic reasons. For instance, when the machine is already running, the session time change buttons are disabled; when the machine is idle, the frequency adjustment buttons are disabled; and when the machine is running on a program mode, all buttons except for the Stop button, are disabled.

We keep sufficient inventory of remote control for immediate shipping on request for any reason.

Remote defective claim rate significantly reduce after we adopted a thick size remote (black color) in 2020.

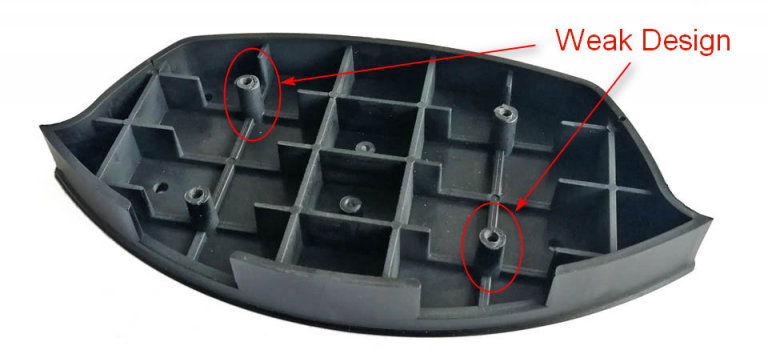

Weak Design of Control Console Base Plate

There are some cases that the control console was broken off from the base. That is because of a design flaw of the control box base piece. The picture below shows the bottom view of a control box base piece. The four cylinder shape screw holders are a bit thin. They have enough strength to endure vibration in regular use. However, accidental impact, usually in transportation, can break these cylinders. This base piece can be easily replaced only using a screw driver.

Clunk sound is NOT a Quality Problem

You will hear a clunk sound from the machine when you start the machine or switch the amplitude between Hi and Lo while the machine is running.

You will also hear the same clunk sound in P3 mode when the machine automatically switch the amplitude.

This is not a quality issue.

This clunk sound is produced because eccentric wheel strikes the postion block when motor starts or reverses its rotation direction. VT003F switches amplitude by reversing motor rotation direction to engage more or less eccentric wheel pairs. This strike does not do any hurt to the machine. It is not an problem. You are supposed to hear such a sound when switching the amplitude.

In P3 mode, the machine automatically switches the amplitude multiple times in a session as programmed. Therefore you will hear clunk sound each time when the amplitude is switched, and you know the amplitude is switched when you hear the sound.