VT003F Development History

History of VT003F

VT003F High Frequency Vibration Plate was originally designed by Jintuo Mechanical & Electrical Manufacturing Ltd. The model was first launched in German market in 2012. After several rounds of modifications, VT003F has become successful, selling well through fitness clubs in Germany.

At the end of 2017, SpecsPro LLC secured VT003F's exclusive market right in North America, and started to re-launch, promote and sell this model with exceptional customer services and preferrable warranty terms.

In 2018, SpecsPro LLC acquired the ownership of VT003F's design and initiated a series of improvements on quality, performance and consistency. We conducted in-depth analysis of the quality issues through customer feedbacks, defect study, tests and experiments, and worked very closely with the original designer and the production team on design optimization, component sourcing and quality assurance. We make improvement in every production batch.

By mid 2021, over 8000 units of model VT003F has been sold in the US. This high frequency linear vibration machine has achieved favorable market recognition for its uniqueness, performance and reasonable price. Most significantly, this type of vibration has been accepted by thousands of users for its health benefits.

We continue to make every effort to improve the quality and performance, and deliver VT003F to customers with exceptional customer services.

Major Improvements on VT003F

From 2018 to 2020, we have launched a series of quality and performance improvement initiatives for VT003F.

2018 Improvement

In 2018, the major investment was made to improve the precision of the die casting molds for motor and bearing houses assembly. The effort was to make the center axis of the two bearing houses highly aligned, so that the motor rotor can rotate much more smoothly at high speed. This improvement significantly reduced the mechanical noise and increased motor and bearings' life span. The first production batch with this improvement was launched to the market exactly on the first day of 2019 (2019 version).

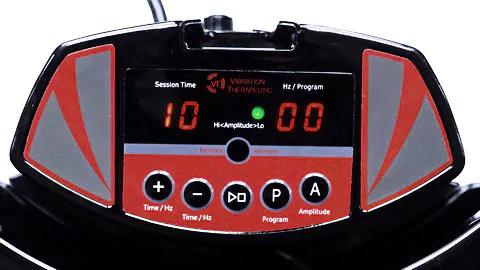

Another notable change to the 2018 version was the vibration frequency control and display. Many customers suggested to have the control panel to change and display frequency (15Hz - 40Hz), instead of speed level (1-20). Therefore, users do not need to look up the user manual to find the relationship between the speed level and the vibration frequency. The control panel directly display vibration frequency in hertz.

2018 version control panel

( displaying speed level)

Current version control panel

(displaying frequency Hz)

2019 Improvement

In mid 2019, we made improvements on the PCB board by the carefully examination of the bill of materials and replaced some key electronic components with high reliable ones, including replacing the most critical component, the amplifier transistor. The goal was to eliminate control panel malfunction that was reported before.

Power Coating+EVA Dip vs. Power Coating

Another important change on this mid 2019 improvement initiative, is adding a thick EVA hot dip coating on the powder coated supporting springs.

With the thick EVA covering the whole spring, the mechanical noise from the spring itself and the connection parts are reduced. This also reduced the excessive noise when the user stands on the upper plate not centered. (2019V2)

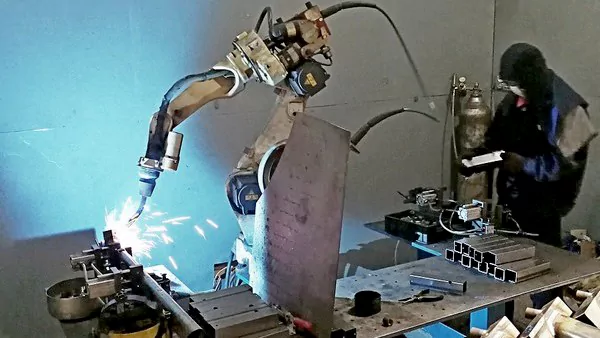

In 2019, an enhanced quality assurance program is implemented in Jintuo. Production batch number is introduced in the quality assurance system to track production time, name of operators and foreman of each production and inspection processes, procumbent of parts and components, etc. This initiative help define and track responsibilities. Issues can be identify during the production processes and the correction can be made in a timely manner.

2020 Improvement

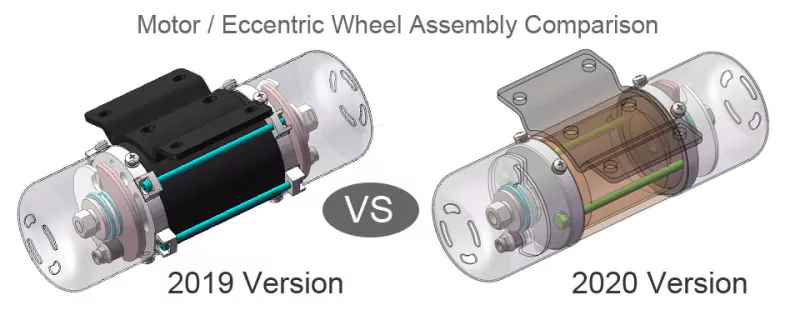

In 2020, a major design change of the motor-eccentric wheel assembly was made. In the original design, the bearing house covers on the two side of motor body are connected using 4 long bolt from outside of the motor shell. This design is easy for the machining of the parts, but the assembly process needs to be very careful to make sure the center of the two bearing houses are aligned. However, with this design, the accuracy depends on worker's skill in the assembling process. Low accuracy would create the stress on the bearings, which would increase the noise and reduce the bearing life.

In our new 2020 design, the bolts connect the two bearing house covers from inside the motor body shell. The structure is greatly simplified. The assembly process is also simplified. The alignment accuracy of the two bearing house depends on the parts machining precision, less human error. Therefore the assembly quality improved with much better consistency. The result is lowered defective rate and extended machine life. (2020.6 version)

2020.6 version comes with a newly designed remote control. The new remote control is much thicker and utilizes durable silica buttons. This reduces the remote control defective rate. With the new thicker design, we put in the 2020 version a thicker lithium battery CR2032 which will last longer. In the 2019 version, the battery was CR2025.

For VT003F machines sold before June 2020, we keep sufficient inventory of remote controls for free replacement.

Please note that the remote control for VT003F needs to point to the signal receiving window on the control panel to work. It is same to a TV remote control, a infrared signal type. Some customer reported remote control issue because they did not point the remote control towards the control panel.