Construction & Mechanics of VT007 / VT009

VT007 and VT009 are both linear vibration plates that uses eccentric wheel device to create vibration movement.

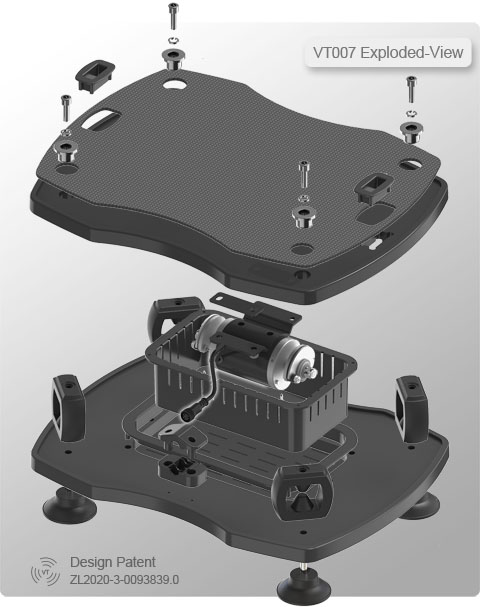

Construction

The machine frame of VT007 consists of an upper board and a lower board, connected by four rubber springs positioned between them. Each board is made of high-density fiberboard and reinforced with a strong ABS outer ring mold-injected around the board.

A motor-eccentric wheels assembly (vibration drive) is mounted on the upper board from below.

The control console is separated from the main machine body. It is connected to the motor using a secure connector.

Mechanics

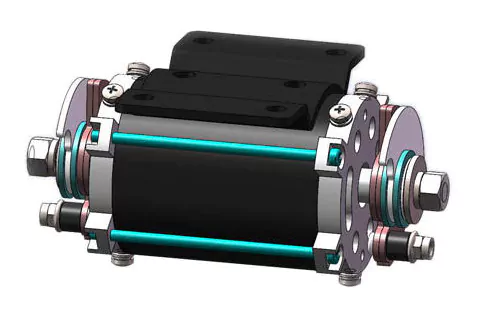

The vibration actuator is an assembly consists of a DC motor and 3 pairs of eccentric wheels. The DC motor rotates the eccentric wheels to create centrifugal force that pushes the upper board to move in an oval pattern.

The movement is regulated by the four strong rubber springs that support the upper board, and form the desired vibration directions. The upper plate moves mainly up-and-down, and modestly forth-and-back.

Vibration frequency is adjusted by the control console through changing the DC motor's input voltage.

The amplitude setting can be switched between high and low by changing motor rotation direction, which engage different numbers of eccentric wheels.

There is a clunk sound when the amplitude setting is switched. This is a normal sound. It does not harm the machine.

Two Amplitude Settings

VT007’s daul-amplitude design was inspired by the amplitude-switching technology long used in industrial road-compactors. Its mechanical logic follows the principles described in an expired U.S. patent—US 4,830,534 (Dual-amplitude vibration generator for compaction apparatus), originally filed in 1987.

The vibration drive of VT007 consists of three pairs of eccentric wheels. These pairs generate centrifugal forces that create the reciprocating movement. One of the three pairs can be rotated to the opposite position, allowing it to cancel the centrifugal force produced by one of the other two pairs. This position change is simply achieved by reversing the motor’s rotation direction. Such a device is:

- mechanically simple

- highly reliable

- low cost

- easy to control electronically

- capable of generating clean linear motion (ideal for therapeutic vibration)

By adopting this technology, we designed Model VT007 with two amplitude settings:

| Model VT007 | ||

| Amplitude Setting | Lo | Hi |

| Eccentric Wheels in Effect | 1 Pair | 3 Pair |

| Amplitude Range | 0.7 - 1.2mm | 1.5 - 2.6mm |

Compared with VT009

For the Model VT009, we added one more set of eccentric wheels, and the result is:| Model VT009 | ||

| Amplitude Setting | Lo | Hi |

| Eccentric Wheels in Effect | 2 Pair | 4 Pair |

| Amplitude Range | 0.8 - 1.4mm | 1.7 - 3.1mm |

The four-pair eccentric-wheel system in the VT009 produces approximately 33% more centrifugal force than the three-pair system used in the VT007. This increase in driving force translates into an average 15–20% gain in vibration amplitude.