Vibration Plate Model VT007

VT007 is a consumer grade linear vibration plate featuring adjustable frequency from 10Hz to 40Hz and two amplitude settings.

| Movement Pattern & Key Parameters | |

Linear Vibration Linear Vibration |

|

Index for Content Below

- Product Overview

- Tech Specifications

- Frequency & Resonance

- Control Features

- Issues & Warnings

- Quality & Warranty

- Noise & EMF

- Product Photos

- Where to purchase

- Shipping & Customs

Product Overview

Model VT007 was developed from our legacy linear vibration plate VT003F (sold over 12,000 units in the US), which has earned strong recognition for improving musculoskeletal conditions, activating neuromuscular function, and enhancing peripheral circulation.

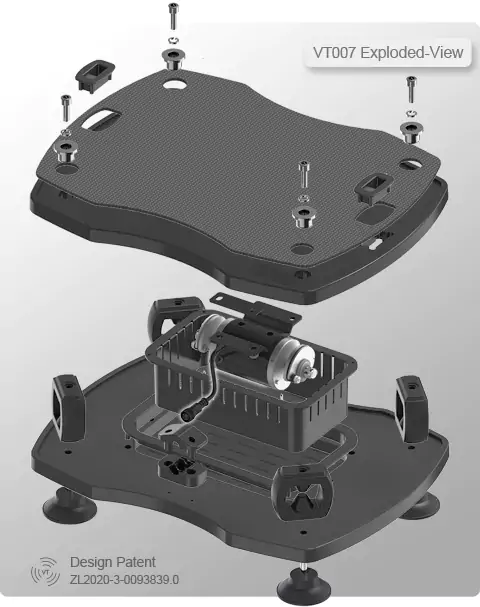

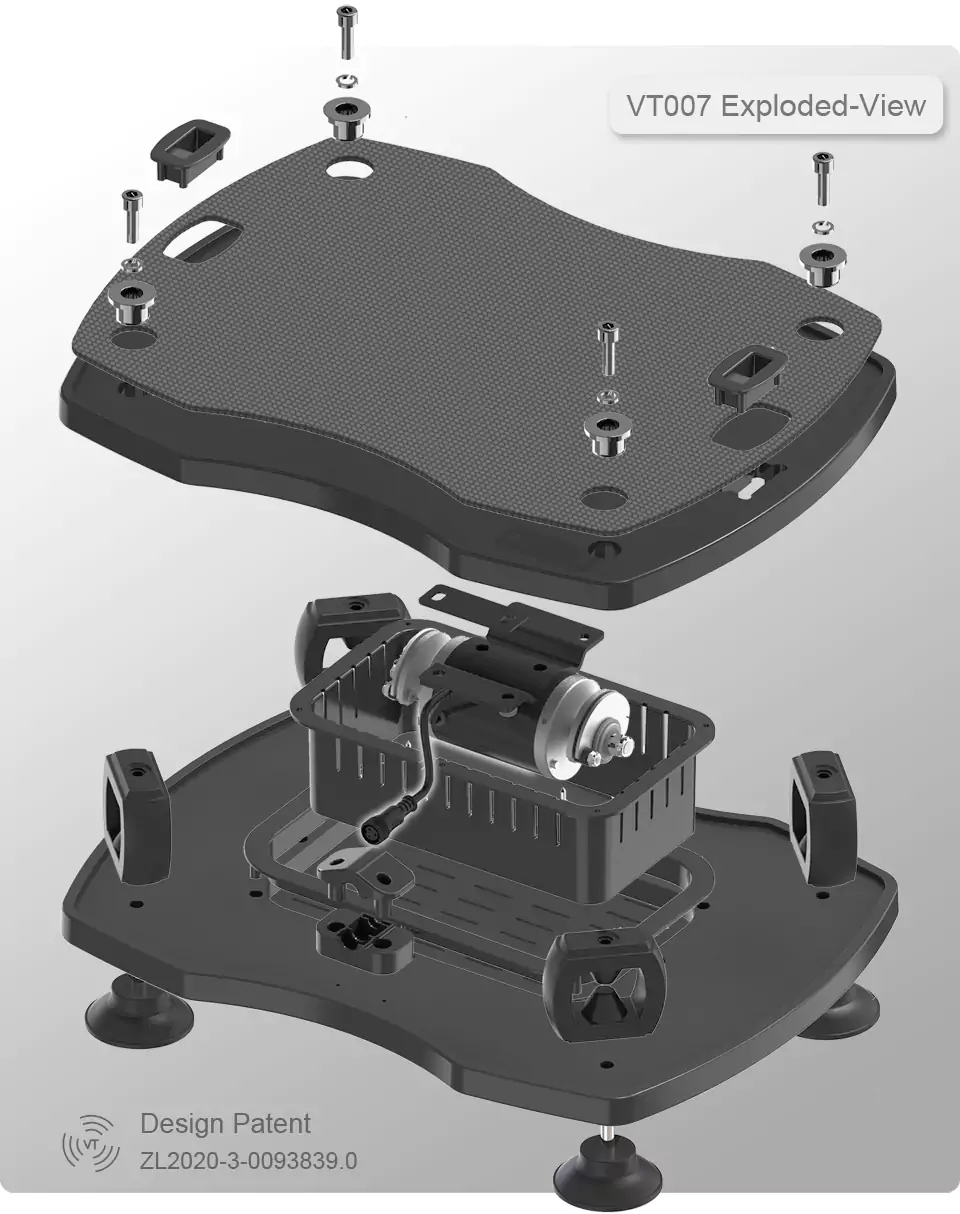

VT007 retains the proven movement pattern and performance parameters of VT003F, but features a simplified mechanical structure and reinforced construction for greater reliability and durability.

More than built-to-last, VT007 showcases a timeless aesthetic appeal through its simplicity, solidity and the elegant style.

Hand Straps Discarded

The latest version VT007 no longer includes hand straps. The earlier version came with a pair of non-elastic straps, intended to assist with balance. In practice, however, this was misleading and potentially unsafe. In practice, users of VT007 don't find these hand straps are useful.

Therfore, we have completely discarded the hand straps in the latest VT007 design.

If balance support is needed, it is best to use a rigid, stable aid — such as a handrail or a heavy piece of furniture.

Tech Specifications

| Vibration Pattern | Linear Vibration |

| Vibration Frequency | 10 - 40 Hz Adjustable, 1 Hz incremental |

| Amplitude at Hi |

1.5 - 2.6 mm without load |

| Amplitude at Lo | 0.7- 1.2 mm, without load |

| Nominal G-force | @No Load: 0.2 - 3.3 @180Lb: 0.1 - 2.7 |

| Machine Size | 560mm x 420mm x 145mm L22" x W16.5" x H5.7" |

| Machine Net Weight | 10.4 kg / 23 lb |

| Electric Motor | 80W PMDC Motor, 900‑2400RPM |

| Power Supply | Universal 100V-240V |

| Max User Body Weight | 110 kg / 250 lb |

Frequency & Resonance

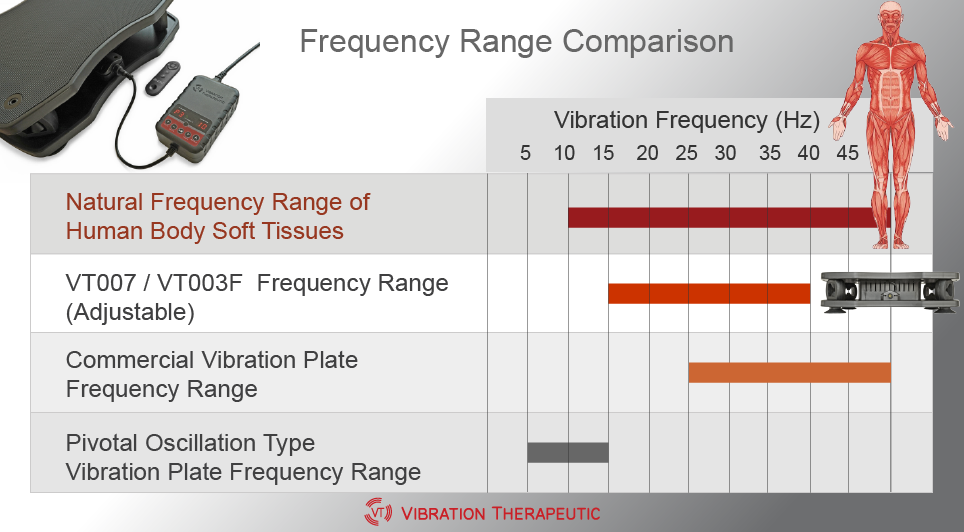

VT007's vibration frequency range is specifically designed to align with the natural frequency of skeletal muscles, for creating a resonance effect.

At resonance, the vibrations most effectively induce muscle contractions, providing an intense and rapidly repeated mechanical stimulation to both the musculoskeletal and neuromuscular systems. Vibration therapy utilizes this unique simulation for health improvement.

The chart below exhibits vibration frequency ranges of different types of vibration plates, compared to the natural frequency of human body soft tissues.

Not a Medical Device

VT007 is sold as an exercise equipment. Please consult a medical professional if you intend to use this device to treat a medical condition.

When properly used, VT007 can induce rapidly repeated skeletal muscle contraction, which can enhance the physical exercise effectiveness.

The unique muscle contraction stimulation may be used as a therapeutic intervention for musculoskeletal, neuromuscular and circulatory disorders. The physiological processes behind muscle contraction are beneficial for self-healing and general health improvement.

If used incorrectly, vibration may adversely impact the user.

Please read the disclaimers, cautions and exceptions on our website. The health benefits suggested or implied on our websites and product literature are not certified or endorsed by any regulatory authority or medical institute.

Control Features

The use of VT007 is simple and intuitive. Users can easily adjust the session time, frequency, and amplitude using either the control console or the remote control. The buttons on the control panel perform the same functions as the corresponding buttons on the remote control.

Before starting the vibration, user can choose manual control mode or any of three program control modes, then press Play button to start the session.

Manual Control

In manual control, user can adjust the following parameters.

| Session Time | 1 - 20 minute, default 10 minutes |

| Frequency | 15 - 40 Hz, one hertz incremental |

| Amplitude | Lo / Hi switch |

Program Control

Three program control modes (P1, P2 and P3) are built-in with VT007. Each program automatically run a spectrum of frequencies, changing every 5 seconds, within a total session time of 10 minutes.

In P3 mode, amplitude switch is added to the frequency change spectrum.

The charts below exhibit the frequency and amplitude pattern of each program control mood.

Time Line (Second)

Time Line (Second)  Time Line (Second)

Time Line (Second)  Time Line (Second)

Time Line (Second)Green dot: Low Amplitude | Red dot: High Amplitude

Issues & Warnings

Floor Vibration Issue

VT007 should be used on a solid floor that resists vibration. It is recommended to put the machine on a carpet or exercise mat so as to prevent the machine from jumping or drifting on the floor.

While VT007 transmits most vibration to the user, it also transmits some vibration to the floor.

We don't recommend using VT007 on a wood frame floor that is connected to the wall. VT007 can vibrate the floor and the connected building structure, making extra noise. Over time, vibration may cause damage to the house structure.

Floor vibration is a major issue that limits the use of a high frequency vibration machine like VT007 in wood-frame construction houses.

Use VT007 on an exercise mat

Use VT007 on an exercise matDepending on the solidity of the floor, placing an anti-vibration cushion beneath the machine may be a solution. A large piece of exercise mat made of EVA material, 1/2" thick, may serve this purpose well.

In an wood-frame construction house, VT007 should be used on the ground floor or in the basement.

VT007 should not be used in a mobile home.

Drift on Floor

VT007 has a light weight, the centrifugal force generated by vibration can overcome the machine weight and cause the machine to drift on the floor, especially when there is no body weight on the machine.

Using the VT007 on a floor carpet or on a large exercise mat can effectively prevent the machine from drifting, due to the added buffer and friction.

You should always keep your body on the machine before starting the vibration. Never let the machine to run unattended.

Potential Risks

The risks of using the VT007 vibration plate have not been thoroughly studied.

Clinical trial based scientific studies support that proper use of vibration plate does not pose a health hazard. However, a cautious and risk-averse approach is always recommended.

Individuals with certain medical conditions may not be suited for using the VT007.

The Clunk Sound is NOT an Issue

This is not an issue.

When you start the vibration plate or switch the amplitude between Hi and Lo, you can hear a clunk sound. This is normal, not a problem.

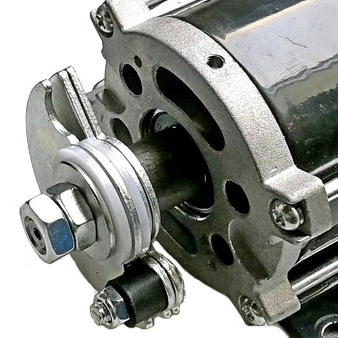

When the machine is started, or amplitude switched, the motor reverses the direction to engage different number of eccentric wheels. In the process, the eccentric wheels strike the position block and make the clunk sound.

In P3 mode, the machine automatically switches the amplitude multiple times in the programmed session. Each time when the amplitude is switched, there is a clunk sound, and you know the amplitude is switched.

You may also hear a metal grounding sound, which is the sound that the eccentric wheels turn on the motor shaft.

These are normal sounds of VT007 in operation, no any harm to the machine.

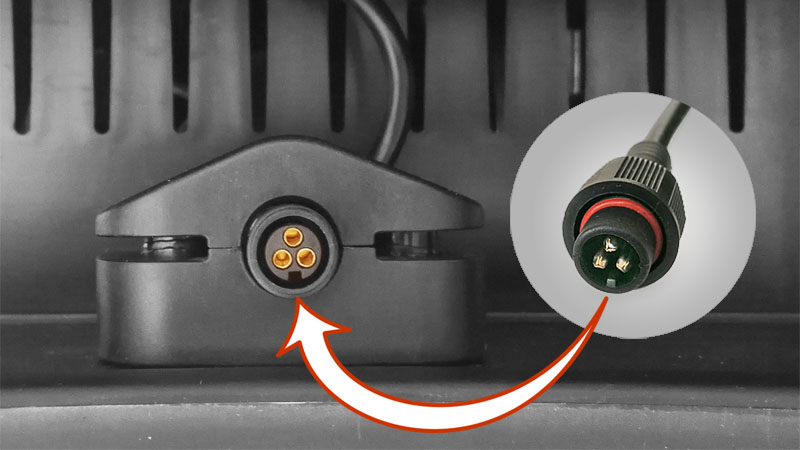

Control Cable Connector Issue of the Latest Version

The lastest version of VT007 has a connector issue. If not aware or not reading the instruction, customer may not inset the plug into the socket in the designed direction (matching the flat-key), resulting in malfunction. If so, unplug the connector and replug it in following the instruction.

Quality & Warranty

| Defective Rate Breakdown (First Year of Use) | ||

| Control Console Failure | 1.2% | Replacement (Plug‑n‑Play) |

| Remote Control Failure | 1% | Replacement |

| Motor Failure | 0.2% | Warranty or self-service |

Replacement parts and modules can be ordered free of charge from our website for at least 10 years after purchasing the machine.

Noise & EMF

Vibration Noise

VT007's noise is a combination of sound wave noises and mechanical noise.

Sound wave becomes audible to human ears when the vibration frequency is about 20Hz. Sound wave noise is not avoidable.

Mechanical noise is produced by the friction and impact between the moving parts of the vibration machine. It is not avoidable, but could be reduced through design optimization, parts precision and assembly accuracy improvement.

Because VT007 is designed for household use, we make good efforts to reduce its mechanical noises, for better user experience.

One of the major source of mechanical noise is the impact and friction between the upper plate and the supporting springs, due to the gaps produced between these two components during vibration. This noise will be greatly reduced when user steps on the machine with body weight centered.

Over time, the vibration can loose the bond between the upper plate and the rubber. There will be more mechanical noise. Tightening up the four bolts at the four corner may solve the issue.

Electromagnetic Fields (EMF)

Like other household electric appliances, VT007 produces electric field and magnetic field (EMF).

For VT007, the main source of magnetic field is from its electric motor. At one foot above VT007's upper plate, the maximum magnetic field strength measured is 1.3 milligauss, and the maximum electric field strength measured is 44V/m.

For an electric motor, the EMF frequency equals the motor rotation frequency. VT007's EMF frequency is no more than 40Hz. EPA classifies this type of EMF as extremely low frequency EMF, or ELF EMF. Scientists have not found ELF EMF poses any safety concern to human.

EPA advises that there is no clear scientific evidence that EMF affects health. EPA does not define a safe or hazardous level of EMF exposure.

Reader's discretion is advised.

Product Photos

Where to Purchase

Purchase VT vibration plate from our VT Amazon Store or VT eStore, same terms and conditions.

- Free shipping to the 48 contiguous states in the US

- Free 90 day return for any reason for full refund, free return shipping

- 10 year warranty, no any out-of-pocket expense for any warranty service

- Exceptional customer service and lifetime support from a professional team that are passionate about vibration therapy and care about customers.

Shipping & Customs

| Package size | 610mm x 470mm x 203mm L24" x W18.5" x H8" |

| Package weight | 14 kg / 30.6 lb |

| HS Code | 9506.91 Articles and equipment for general physical exercise, gymnastics or athletics |

Purchase VT007 on Amazon

Purchase VT007 on Amazon